The propeller shaft stands as one of the most captivating inventions in mechanical engineering, a component that blends history and innovation to keep the world moving. Conceived in the 16th century by Italian engineer Gerolamo Cardano, this vital piece ensures that engine power reaches the wheels, even when shafts are misaligned, making it indispensable in trucks, buses, motorcycles, and industrial machinery. At Leax do Brasil, we take this technology to new heights, merging advanced manufacturing processes with meticulous design to deliver strength, efficiency, and reliability in every application.

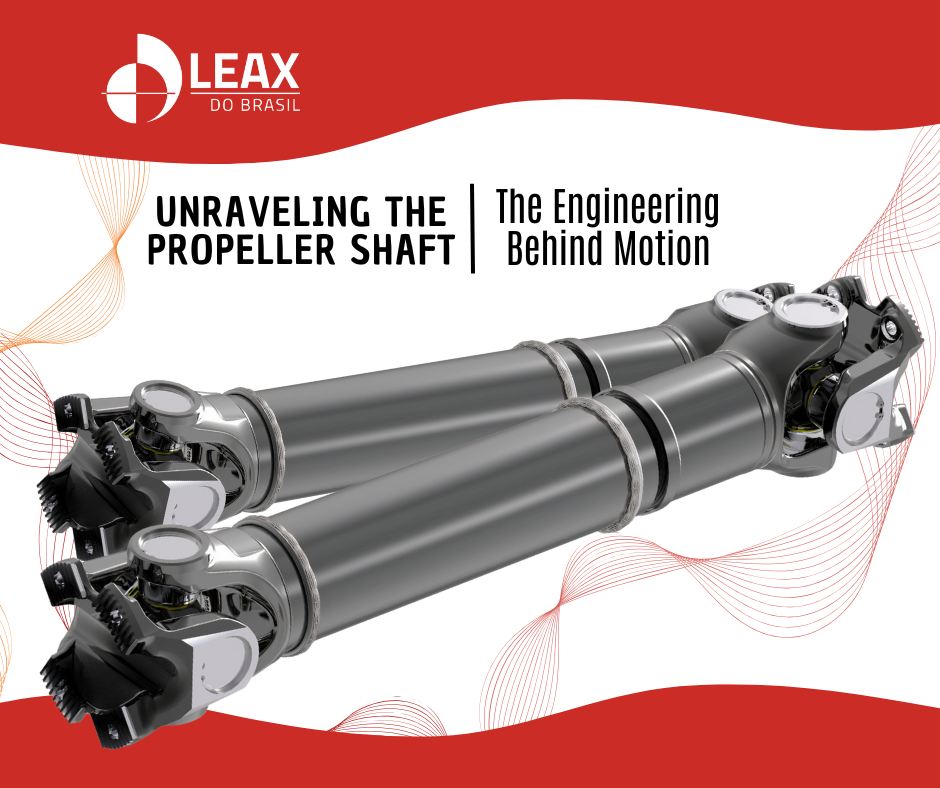

What makes the Leax propeller shaft so exceptional? It all comes down to its core components, each crafted with a specific purpose to ensure peak performance. The tube serves as the backbone of the propeller shaft, a sturdy structure that holds the entire assembly together and withstands intense vibrations or heavy loads. Made with top-grade materials and precision machining, it provides the stability that keeps the system intact. Next, the universal joints, or crosses, act as the articulating heart of the shaft. These allow rotational motion to be transferred at varying angles, adapting to shifts in direction or uneven terrain—like turns or bumpy roads. At Leax, our crosses are dynamically balanced to reduce wear and ensure smooth power delivery.

Another key player is the flanges, which connect the propeller shaft to the transmission or differential. Available in configurations like yoke designs, these components are engineered for a secure and efficient fit, ensuring power flows seamlessly from the engine to the wheels. The precision in crafting Leax’s flanges guarantees perfect alignment, cutting down on vibrations and extending the lifespan of the assembly. Additionally, many of our shafts feature bearings, designed to support continuous motion with minimal friction and no need for frequent maintenance—a practical advantage for those prioritizing cost-efficiency and uptime.

At Leax do Brasil, every component is born from a production process that includes high-precision machining and dynamic balancing, ensuring the propeller shaft operates as a cohesive, dependable unit. Whether it’s powering a fleet of trucks on long hauls or industrial equipment running nonstop, our propeller shafts are tailored to meet each client’s unique needs. From the tube that endures stress to the crosses that spin effortlessly, every detail showcases our dedication to quality. More than just a mechanical part, the Leax propeller shaft is a testament to how engineering turns motion into progress.

Any questions? Make contact: [email protected]

Leave A Comment